The Heart of Foditec™:

Smart Materials Working Together

Foditec™ kneepads are built from advanced materials designed for both protection and comfort. The dual-density EVA foam combines a hard bottom layer for durability and force distribution with a soft top layer that cushions the knee. At the core, the Foditec™ spring, made of resilient thermoplastic elastomers (High Impact PA6/PP), flexes and rebounds with every movement. Together, these materials power Foditec™ Force Distribution Technology—delivering long-lasting comfort, reliable protection, and unmatched pressure relief.

Water ResistanCE

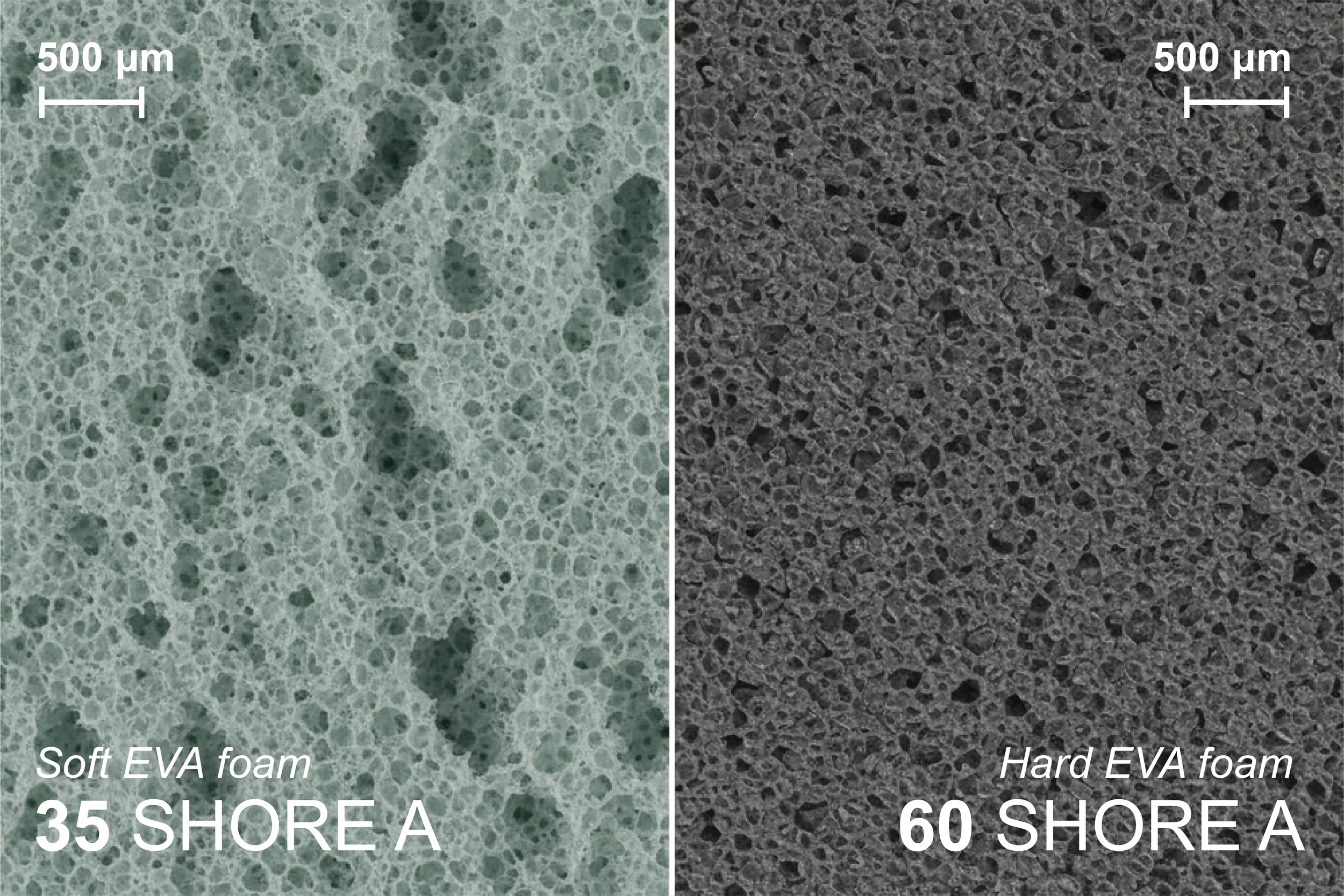

Liquids cannot penetrate EVA through the closed-cell structure, ensuring that moisture, oils, or other contaminants remain on the surface instead of being absorbed. This property not only protects the integrity of the FODITEC™ protectors in demanding work environments, but also makes it exceptionally easy to clean. Dirt and spills can be quickly wiped away, allowing the protectors to remain hygienic and ready for use over extended periods of time.

-

EVA Foam: Dual-Density Comfort & Protection

Foditec™ kneepads use high-quality EVA foam in two degrees of softness. The hard EVA bottom (60 Shore A) resists wear and spreads impact on rough surfaces, while the soft EVA top (35 Shore A) cushions the knee for lasting comfort. This smart combination works seamlessly with Foditec™ Force Distribution Technology to deliver maximum protection and relief.

-

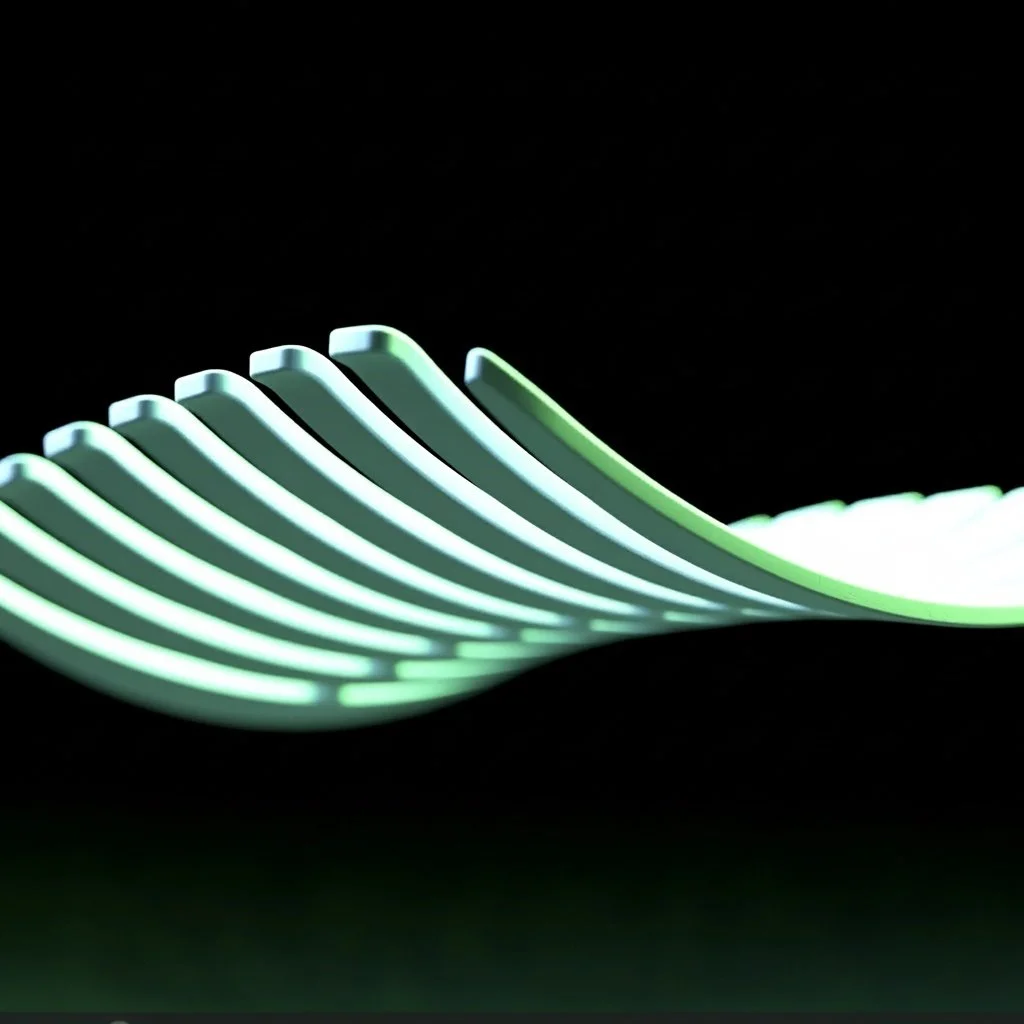

Polypropylene for durability and flexibility

At the core of Foditec™ kneepads lies a precision-engineered spring made from high-grade Polypropylene (PP). This advanced polymer combines flexibility with strength, allowing the spring to absorb pressure and instantly rebound. Unlike metal, PP is lightweight, non-corrosive, and highly durable—ensuring reliable support through thousands of kneeling movements.

PUNCTURE RESISTANCE

EVA is widely recognized in industrial applications for its excellent puncture resistance. Unlike softer foams that compress or tear under sharp pressure points, EVA maintains structural integrity and distributes the load across a larger surface. This makes it highly effective against common hazards on the work floor such as nails, screws, or debris.