Pressure distribution testing

The true measure of knee protection is how well it spreads force across the joint. Traditional foam pads compress unevenly, creating pressure peaks that can still damage cartilage. FODITEC Technology™ solves this with its patented spring element, engineered to distribute load evenly. To prove performance, each design undergoes advanced pressure-mapping tests in both laboratory and field settings. These tests visualize exactly how force is absorbed and spread, showing up to 60% lower peak pressure compared to conventional pads. The result: consistent, verified protection that reduces strain and safeguards knee health throughout a professional career.

Climatic tests

Knee pads often fail when exposed to extreme temperatures. Foam hardens in the cold, losing flexibility, and softens in heat, reducing protection. For professionals working outdoors year-round, this means inconsistent performance and higher risk of injury. FODITEC Technology™ is engineered to perform in all climates. The patented spring element and durable shell materials have been tested at both high and low temperatures, ensuring stable pressure distribution regardless of the weather conditions.

puncture test

On real worksites, sharp debris, nails, and rough surfaces constantly threaten to puncture knee pads. Once compromised, protection quickly fails. FODITEC Technology™ is engineered with a reinforced outer shell and tested under strict EN 14404 puncture test standards. In these tests, sharp objects are pressed into the pad under controlled force to verify resistance. Foditec consistently withstands penetration, protecting both the spring system inside and the user’s knees. This durability not only ensures reliable safety in harsh environments but also extends product lifespan—delivering long-term value and dependable performance even on the toughest job sites.

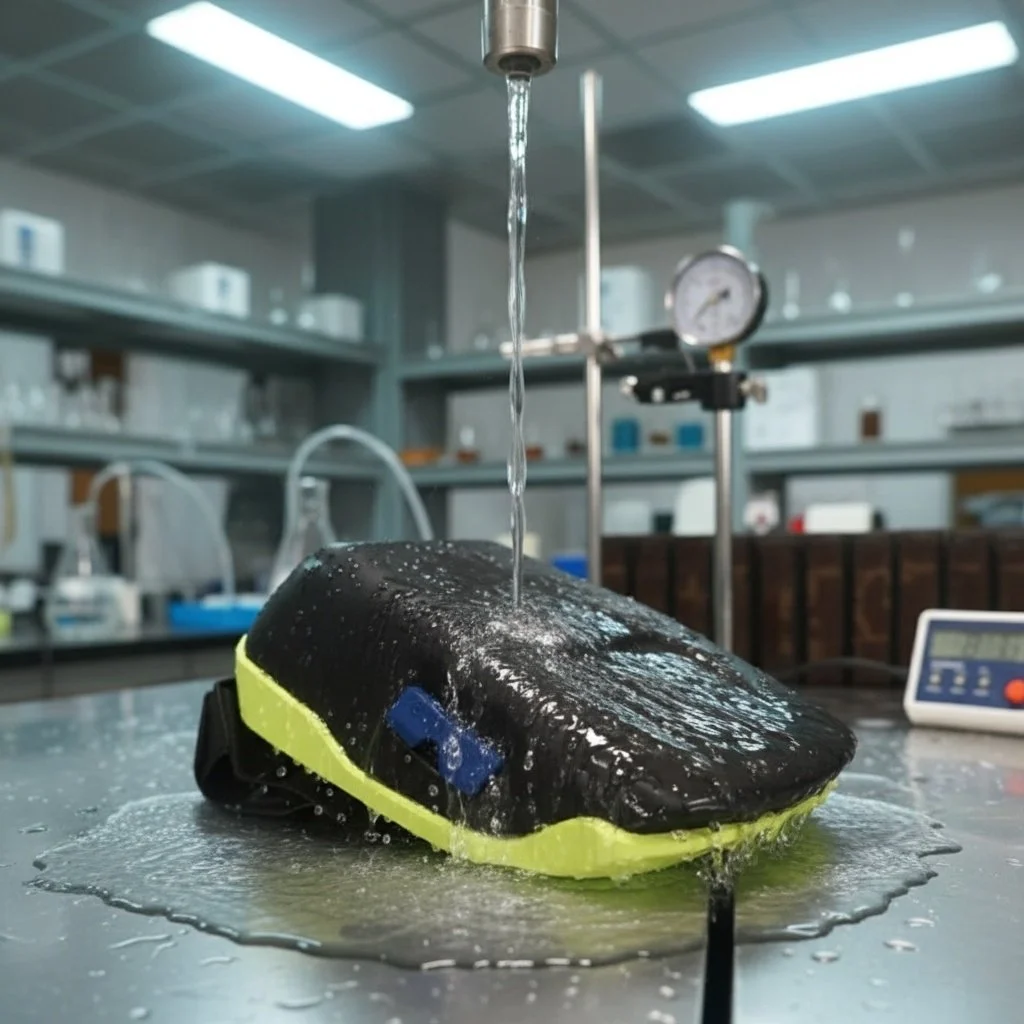

tested for waterproofness

Worksites expose knee pads to rain, wet surfaces, and spilled materials. Many pads absorb moisture, becoming heavy, unhygienic, and prone to damage. FODITEC Technology™ is different. Each product is tested for waterproofness according to strict EN 14404 standards, ensuring no water penetration during use. The sealed shell not only keeps knees dry but also protects the inner spring system from degradation. This waterproof design makes cleaning simple—just rinse or wipe, and the pads are ready for the next job. Durable, hygienic, and reliable, Foditec knee pads are built for demanding conditions indoors and outdoors.

Durability testing

Knee protection only adds value if it performs day after day. Many pads lose cushioning, straps wear out, or materials break down after limited use. FODITEC Technology™ is tested for durability through intensive wear simulations that replicate years of kneeling, flexing, and cleaning. Materials are subjected to repeated stress, abrasion, and compression cycles to confirm long-term resilience. The patented spring element retains its force distribution, while the shell and straps remain intact under tough conditions. This rigorous testing ensures that Foditec knee pads deliver consistent protection, comfort, and reliability throughout their extended service life.